The Role of Proper Pipe Installation in Plumbing Systems

Plumbing systems form the backbone of modern residential and commercial buildings, quietly supporting daily activities such as cooking, cleaning, sanitation, and heating. At the center of these systems lies pipe installation, a process that directly influences performance, durability, and long-term reliability. Properly installed pipes ensure consistent water pressure, safe waste removal, and protection against leaks that can damage structures over time. When installation is handled with attention to layout, materials, and connections, plumbing systems operate efficiently and remain dependable for decades. Understanding how correct pipe installation supports overall system health helps property owners appreciate its value beyond what is immediately visible.

How Proper Installation Shapes System Performance

Foundations of Pipe Layout and Planning

Pipe installation begins long before materials are cut or joined. Careful planning determines how water supply and drainage lines move through walls, floors, and ceilings. Contractors assess building design, usage demands, and code requirements to create layouts that promote efficient flow and accessibility. Proper spacing, slope, and alignment reduce stress on joints and prevent issues such as standing water or pressure imbalances. In this stage, the role of a Plumber becomes especially important, as practical experience helps translate plans into functional systems. When layout decisions are made thoughtfully, future maintenance becomes simpler, and the system adapts more easily to changes or upgrades without extensive reconstruction.

Material Selection and Connection Integrity

The choice of pipe materials significantly affects system performance and longevity. Copper, PVC, PEX, and cast iron each have characteristics suited to specific applications, temperatures, and pressures. Proper installation ensures that materials are used where they perform most effectively and are joined using compatible fittings and techniques. Secure connections prevent leaks and reduce the risk of corrosion or separation over time. Installers must also account for expansion and contraction caused by temperature changes, allowing pipes to move slightly without stressing joints. Attention to these details during installation minimizes wear and helps the plumbing system maintain consistent performance across varying conditions.

Why Installation Precision Matters

Precision during installation influences how a plumbing system responds to daily use. Pipes that are cut cleanly, aligned correctly, and sealed properly allow water to flow smoothly with minimal turbulence. This reduces noise, wear, and pressure fluctuations that can strain fixtures and appliances. Even small errors, such as uneven slopes or over-tightened fittings, can lead to recurring problems that worsen over time. Installation precision also supports compliance with building codes, which exist to ensure safety and reliability. By following established standards and applying careful workmanship, installers help create systems that function quietly and efficiently behind the scenes.

Installation and Long-Term Durability

Proper pipe installation plays a major role in how long a plumbing system lasts. When pipes are supported adequately and protected from physical stress, they resist cracking, sagging, and separation. Installers use brackets, hangers, and insulation to stabilize pipes and shield them from temperature extremes or vibration. This approach reduces fatigue on materials and extends their service life. Long-term durability also depends on avoiding shortcuts during installation, as rushed work often leads to hidden weaknesses. Investing time and care during installation helps ensure that pipes remain reliable components rather than sources of recurring repairs.

See also: How do HVAC Contractors Address Noise Reduction in Modern Systems?

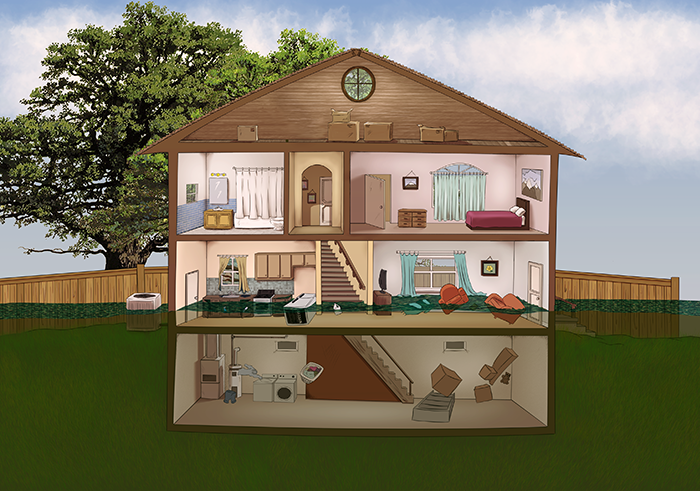

The Hidden Costs of Improper Installation

Improper pipe installation can introduce problems that remain unnoticed until significant damage occurs. Leaks behind walls or under floors may develop slowly, leading to mold growth, structural decay, and costly remediation. Poor alignment or incorrect slopes can cause clogs and backups that disrupt daily routines. These issues often require invasive repairs that exceed the cost of correct installation. Understanding the hidden costs highlights why proper pipe installation should be viewed as a long-term investment rather than a short-term expense. Quality installation protects property value and reduces unexpected disruptions over the life of the building.

Proper pipe installation is a foundational element of effective plumbing systems, influencing performance, durability, and overall reliability. Through careful planning, appropriate material selection, precise connections, and attention to long-term stability, well-installed pipes support consistent water delivery and waste removal. Avoiding installation errors helps prevent hidden damage and reduces maintenance demands over time. By recognizing the importance of installation quality, property owners can make informed decisions that protect their buildings and ensure plumbing systems remain dependable. A well-installed piping network may go unnoticed day to day, but its impact is felt through uninterrupted comfort, safety, and efficiency.