Why Ignoring Minor AC Issues Can Lead to Major Repairs?

Air conditioning systems are designed to operate smoothly for long periods, but they rely on many interconnected components working in balance. When small issues appear, they often seem harmless at first. A faint noise, slightly warmer air, or longer run times may not feel urgent, especially during busy seasons. However, these early warning signs usually indicate underlying stress within the system. Ignoring them allows problems to grow quietly, affecting performance, energy use, and internal parts. Over time, what began as a minor concern can develop into a costly repair that disrupts comfort and daily routines. Understanding how small AC issues escalate helps homeowners appreciate the value of timely attention.

How Small Problems Turn Into Bigger Ones

Early Warning Signs and Hidden Stress

Minor AC issues rarely stay isolated. A loose electrical connection, clogged filter, or slightly low refrigerant level creates strain across the system. The unit compensates by working harder to maintain desired temperatures, which increases wear on motors and compressors. Homeowners often dismiss early symptoms because the system is still running, but internal stress continues to build. In many service calls involving Vista air conditioning, technicians find that long-ignored minor issues were the starting point for significant mechanical failure. Addressing early warning signs helps prevent this chain reaction, protecting the system from unnecessary strain and reducing the risk of sudden breakdowns.

Efficiency Loss and Increased Operating Load

When minor issues go unresolved, efficiency gradually declines. Restricted airflow or inaccurate thermostat readings force the system to run longer cycles. This increased operating load raises internal temperatures and accelerates component fatigue. While the system may still cool the space, it does so less efficiently, consuming more energy. Over time, the added workload shortens the lifespan of key parts. What might have been a simple adjustment or cleaning task can turn into a major repair involving expensive components. Efficiency loss is often one of the earliest and most overlooked consequences of ignoring small AC problems.

Refrigerant Imbalance and System Strain

A slight refrigerant imbalance may not immediately stop cooling, but it affects how the system transfers heat. Low refrigerant forces the compressor to work harder, increasing pressure and temperature within the system. This stress compounds over time, potentially leading to compressor damage. Because the compressor is central to cooling, repairs to this component are often extensive. Identifying and correcting refrigerant issues early prevents prolonged strain and helps maintain balanced operation. Ignoring this issue allows pressure-related damage to spread through the system.

Electrical Wear and Control Problems

Electrical components such as capacitors, contactors, and wiring are sensitive to irregular operation. Minor voltage fluctuations or loose connections may cause intermittent issues that seem insignificant. Over time, these electrical inconsistencies generate heat and wear down components. A failing capacitor, for example, can prevent motors from starting smoothly, leading to further mechanical stress. Ignoring electrical issues often leads to cascading failures that affect both control systems and mechanical components. Timely attention to electrical concerns helps maintain stable operation and reduces the chance of unexpected system shutdowns.

Airflow Restrictions and Mechanical Impact

Clogged filters, dirty coils, or blocked vents restrict airflow, forcing the system to work harder to move air. This added resistance places an extra load on blower motors and fans. As these components struggle to maintain airflow, they experience increased friction and heat buildup. Over time, motors may overheat or fail. What began as a simple maintenance issue can escalate into motor replacement or extensive repairs. Maintaining clear airflow paths supports smooth operation and protects moving parts from unnecessary stress.

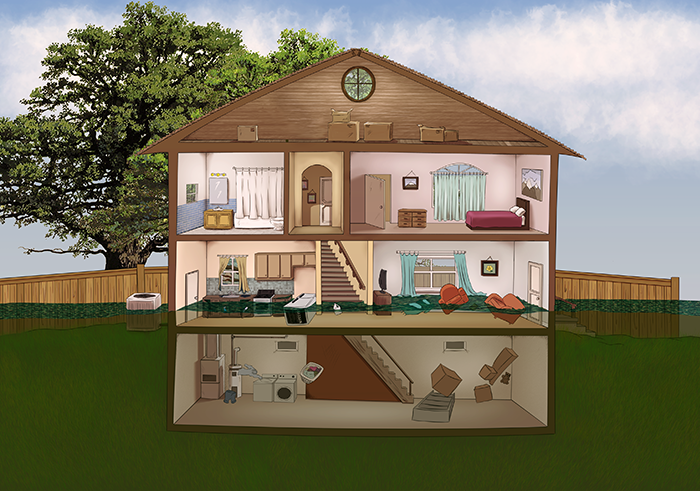

Moisture Issues and Internal Damage

Minor drainage problems, such as a partially clogged condensate line, may go unnoticed until water backs up. Excess moisture can damage nearby components and create conditions that promote corrosion. Corrosion weakens metal parts and electrical connections, increasing the risk of failure. Moisture-related damage often spreads quietly, affecting areas that are not easily visible. Addressing drainage issues early helps protect internal components and prevents water-related complications that can significantly increase repair costs.

See also: Global Lending Phone Number: Contact and Services

System Imbalance and Component Fatigue

Air conditioning systems are designed to operate within specific performance ranges. Minor issues push components outside these ranges, creating an imbalance. For example, uneven cooling may indicate airflow or duct issues that cause certain parts of the system to operate more efficiently than others. This uneven workload accelerates fatigue in stressed components while others remain underutilized. Over time, this imbalance increases the likelihood of part failure. Restoring balance early helps distribute workload evenly, supporting longer system life and more reliable operation.

Noise and Vibration as Warning Signals

Unusual sounds or vibrations are often dismissed as normal aging, but they frequently signal underlying issues. Loose mounts, unbalanced fans, or worn bearings can cause vibrations to travel through the system. These vibrations loosen connections and accelerate wear in adjacent components. Ignoring noise allows vibration-related damage to compound, affecting both mechanical and structural elements of the system. Early investigation of unusual sounds helps prevent vibration from becoming widespread.

Comfort Decline and User Adjustments

When minor AC issues reduce comfort, occupants often compensate by adjusting thermostat settings. Lowering the temperature to counter weak cooling forces the system to run longer and harder. This response increases strain without addressing the root cause. Over time, these adjustments contribute to system fatigue and higher repair risk. Recognizing changes in comfort as warning signs encourages proactive solutions rather than temporary fixes that increase stress on the system.

Financial Impact of Delayed Repairs

Ignoring minor AC problems often leads to higher repair costs over time. Small fixes are generally less disruptive and less expensive than major component replacements. When issues escalate, repairs may require multiple parts and result in extended downtime. The financial impact extends beyond repair bills to include discomfort and potential damage to indoor environments. Addressing issues early helps manage costs predictably and avoids sudden, large expenses.

Long-Term Reliability and System Health

Consistent attention to minor AC issues supports long-term reliability. Systems that receive timely care operate more smoothly and maintain stable performance. Early intervention prevents small problems from escalating into larger failures. Over time, this approach reduces repair frequency and extends system lifespan. Reliable operation also contributes to consistent indoor comfort and fewer disruptions. Viewing minor issues as opportunities for preventive care rather than inconveniences shifts maintenance from reactive to proactive.

Ignoring minor AC issues allows small problems to escalate into major repairs due to cumulative stress, imbalance, and wear. Early warning signs such as reduced efficiency, unusual noise, or slight changes in comfort indicate underlying strain in the system. Addressing these concerns promptly protects key components and supports balanced operation. Understanding how minor issues escalate highlights the importance of timely attention. By responding early, homeowners can reduce repair costs, extend system life, and maintain consistent comfort without facing unexpected breakdowns.